Materials and their properties

|

Material

|

Types

|

Properties

|

Examples

|

|

Plastics/

Polymers

|

Thermoplastics

|

High degree of plasticity, recyclable

|

Perspex™, PVC, ABS, Polystyrene

|

|

Thermosets

|

Medium degree of plasticity, non-recyclable

|

Polycarbonate, Nylon, Teflon™

|

|

Timber

|

Natural - Softwood (Evergreen)

|

High tensile strength, mid-density, mid-compression

|

Pine, Cedar

|

|

Natural - Hardwood (Deciduous)

Temperate

Tropical

|

High tensile strength, high density, high compression

Lighter in color

Darker in color, denser

|

Oak, Ash

Mahogany, Teak, Ebony

|

|

Man-made timber

|

Cheaper, greater widths

|

Plywood, MDF, Chipboard

|

|

Metals

|

Ferrous

|

Contains iron, therefore rusts, hard

|

Steel, Stainless Steel Iron, HSS (High-Speed Steel)

|

|

Non-ferrous

|

Does not contain iron, therefore doesn’t rust

|

Aluminum, Silver, Copper, Gold, Brass, Duralumin

|

|

Alloys

|

Dependant on the ratios and materials

|

Steel, Brass, Duralumin

|

|

Glass

|

Glass

|

Low plasticity, high elasticity, low tensile strength, high compressive strength, brittle, has thermal properties

|

Soda glass, Borosilicate

|

|

Ceramic

|

Porcelain, China

|

|

Textiles

|

Synthetic

|

Waterproof, high tensile strength, non-absorbent

|

Acrylic, Nylon, Kevlar

|

|

Natural

|

Not waterproof, high tensile strength, absorbent

|

Wool, Cotton, Silk

|

|

Composites

|

Carbon Fiber

|

High strength to weight ratio, multi-purpose, tensile strength, heat resistant

|

Carbon Fiber, GRP, Acrylic

|

|

Thermoset Polymers

|

FE, Urea Formaldehyde

|

Proprieties

|

Physical Properties

|

Definition

|

Mechanical Properties

|

Definition

|

|

Hardness

|

The ability to resist scratching and pressure

|

Toughness

|

The ability to resist penetration

|

|

Elasticity

|

The ability to stretch under force and return to its original form

|

Stiffness

|

The ability to maintain form when under pressure

|

|

Plasticity

|

The ability to stay in the deformed form after the elastic point, permanent

|

Ductility |

The ability to be extruded into thin sheets or wires |

|

Density

|

The mass of a material

|

Tensile strength

|

The measure of a material's resistance to strain (deformation)

|

|

Electrical resistivity

|

A measure of resistance to electrical charge

|

Compressive strength

|

The measure of a material's resistance to stress (pressure)

|

|

Thermal conduction

|

A measure of thermal conduction

|

|

|

Thermal expansivity

|

A measure of thermal expansion

|

Young’s modulus

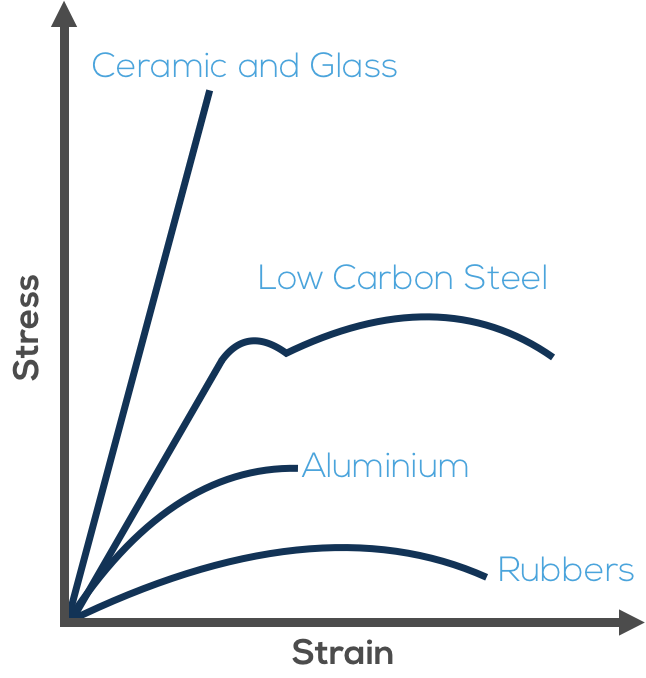

The Young's modulus graphs illustrate the mechanical proprieties of materials by showing the relationship between the stress (force per unit area) and the strain (proportional deformation). Stress is the amount of compression material is experiencing. Strain is the deformation due to the stress.

Stress-strain comparison

Brittle materials have high compressive strength and low tensile strength

Flexible materials have high tensile strength and low compressive strength.

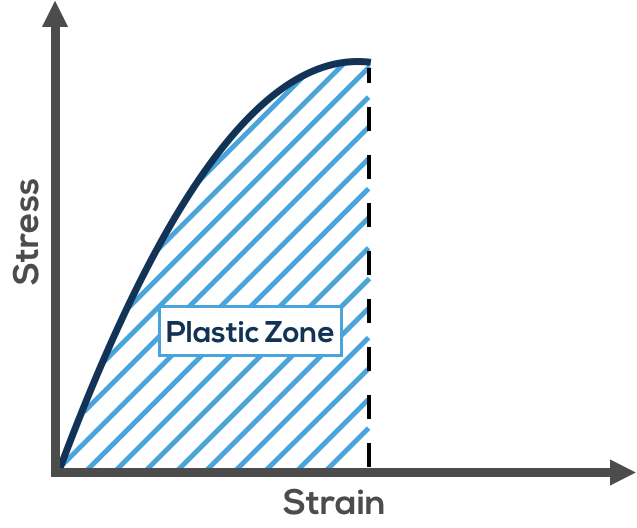

Engineering stress-strain

| Part |

Description |

Diagram |

| Elastic point |

The point where the elastic zone ends |

|

| Yield point |

The point where the Plastic zone starts |

| UTS |

Ultimate Tensile Strength - the maximum load that a material can sustain |

| Breaking point |

The point at which the material fails/breaks |

| Necking |

|

| Elastic zone |

The zone in which a material experiences elasticity |

| Plastic zone |

The zone in which a material experiences plasticity |

Types of steel

| Low Carbon Steel |

High Carbon Steel |

|

|

Protecting materials

Metal from rusting/corroding

Wood

| From |

By |

| Fungi |

|

| Insects |

|

| Weather |

|

Manufacturing

Manufacturing processes

|

Classification

|

Definition

|

Example

|

|

Additive

|

Fusing (gluing) separate pieces of material together

|

Lamination

3D-printing

|

|

Wasting/

subtractive

|

Subtracting (cutting) from a piece of material

|

Laser cutting

Drilling

|

|

Shaping/

machining

|

Subtracting (sanding) from the surface of a material

|

Turning

Milling

|

|

Joining

|

Fixing together two or more components permanently or semi-permanently

|

Nuts, Bolts, Screws, Glue

|

Manufacturing techniques

|

Techniques

|

Type

|

Factors to consider when using this technique

|

Diagram

|

|

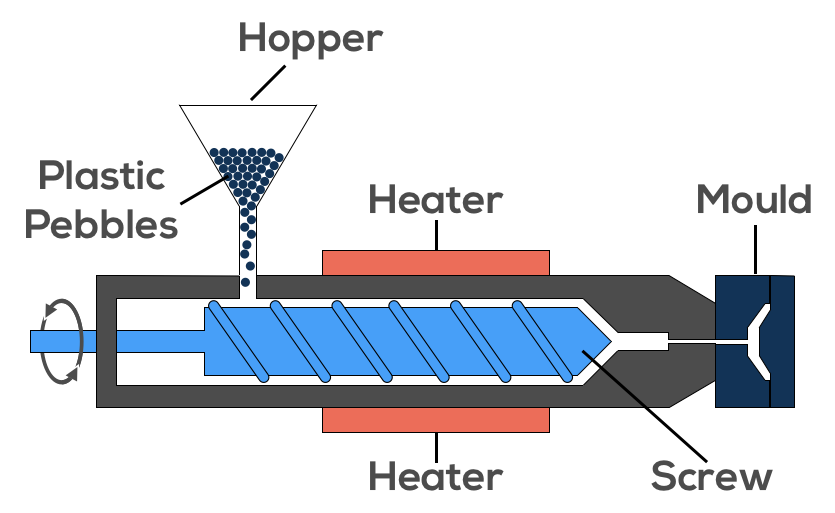

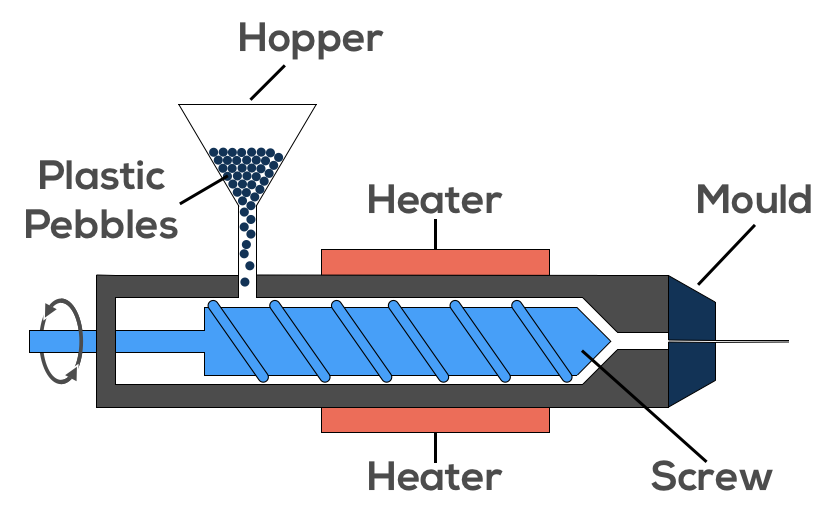

Molding

|

Injection

|

Advantages – no finishing required, volume production, use of different molds

Disadvantages – high capital cost, high cost of molds, size limitations

|

|

| Extrusion |

Advantages – no finishing required, volume production, hollow shapes

Disadvantages – high capital cost, size limitation, shape and detail of extruded parts

|

|

|

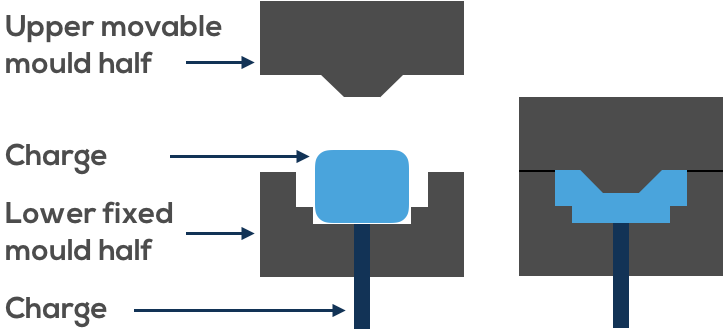

Compression

|

Advantages – no finishing required, volume production, shape and detail

Disadvantages – high capital cost, high cost of molds,

|

|

|

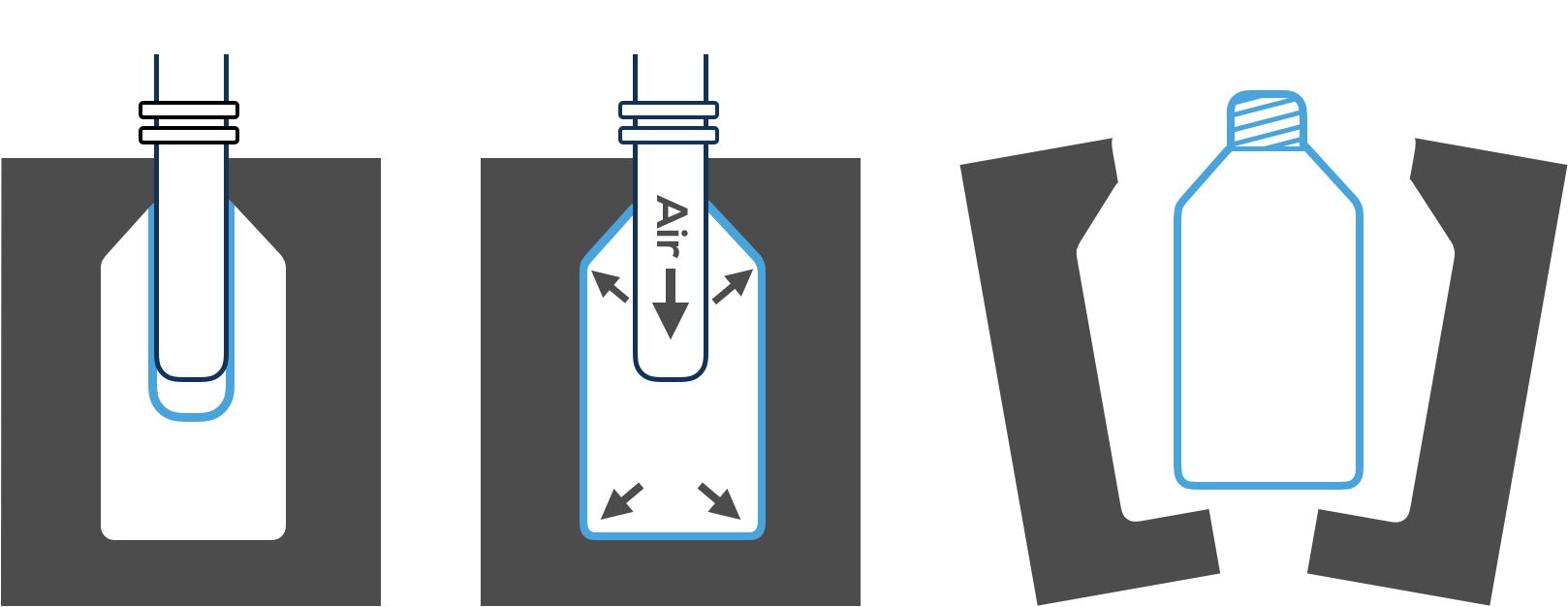

Blow

|

|

|

|

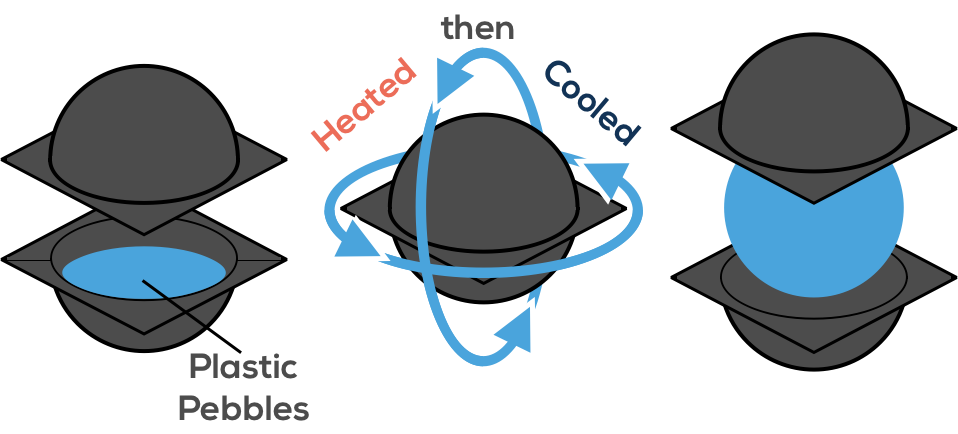

Rotational

|

|

|

|

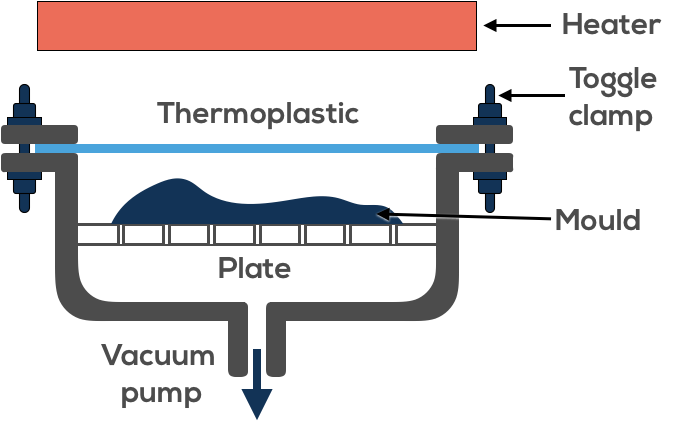

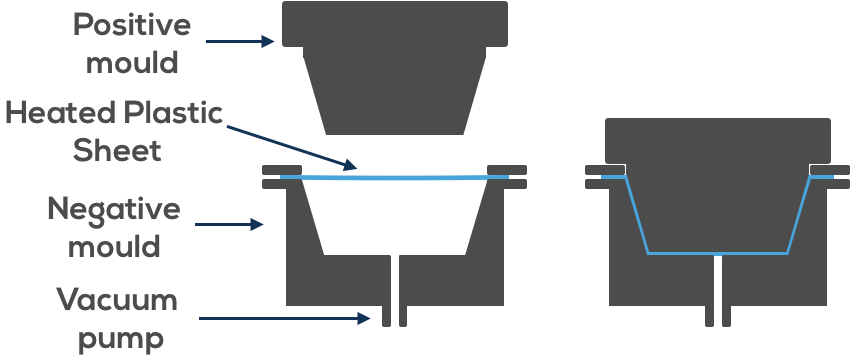

Vacuum

|

|

|

|

Thermoforming

|

|

|

|

Casting

|

Sand

|

|

|

|

High pressure

|

|

|

|

Textiles

|

Weaving

|

|

|

|

Knitting

|

|

|

|

Joining

|

Adhesives

|

|

|

|

Fusing

|

|

|

|

Stitching/

sewing

|

|

|

|

Fasteners

|

|

|

Materials and Techniques

Robots

Robots fulfill a wide range of industrial and non-industrial roles, such as industrial robots, service robots, personal care robots, and medical robots.

| Type of Robot or System |

Description |

| Single-Task Robots |

Robots that perform one specific operation |

| Multi-Task Robots |

Due to their complexity, these robots can perform multiple tasks |

| Team of Robots |

Multiple coordinated robots work together to create an item |

| Machine to Machine (M2M) |

The technology that enables robots to interact with each other and allow the system to operate without human intervention |

Ways fabrication and assembly robots work

| Robots |

Tasks |

Description |

Example |

| Single robot - Single-task |

One robot performing one task |

Welding

|

| Single robot - Multi-task |

One robot performing multiple tasks using interchangeable heads or arms |

Robotic arm with an interchangeable head |

| Multi robot - Single-task |

Multiple robots working together to create one item |

Car assembly line |

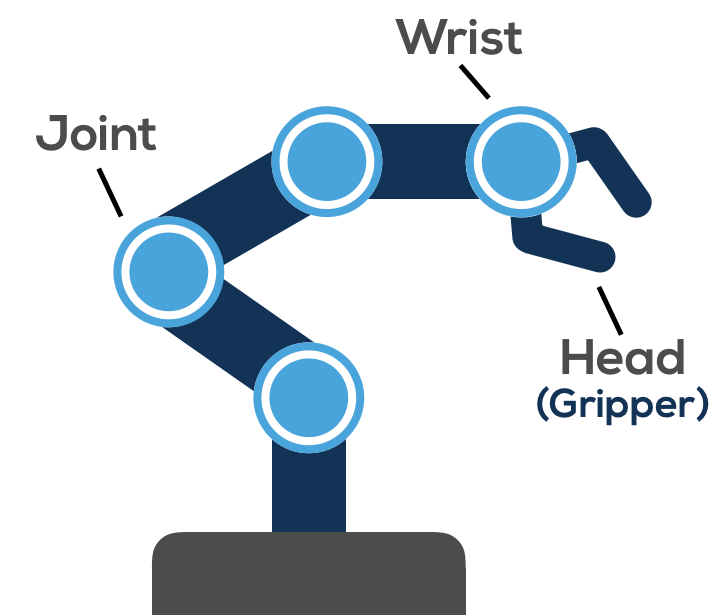

Industrial fixed robotic arm

| Components |

Form |

Diagram |

| Power source |

Electrical, Hydraulic or Pneumatic (Compressed air)

|

|

| Tooling |

Fixed, Multiple or Interchangeable |

| Mechanical Unit |

Structural arm, Sensors, Joints and Actuators (Controllers) |

| Control System |

Computer or Microprocessor driven by a controller |

Scales of Production

|

Scales

|

Definition

|

Example

|

|

Craft/One-off

|

Small-scale - using tools and manual skill and usually made to a client's specific design specifications.

|

Tailored clothing |

|

Batch

|

Medium-scale - using a mixture of manual and mechanical tools to allow individual customization for clients. |

Birthday cakes |

|

Mass/Volume

|

Large-scale - using automized and mechanized tools during the many stages of production in order, which reduces the units. |

Cars |

Design for Manufacture

|

Design for

|

Definition

|

|

Material

|

Taking into account the advantages and limitations of certain materials

|

|

Process

|

Taking into account the different manufacturing techniques

|

|

Assembly

|

Taking into account the stages of the assembly process

|

|

Disassembly

|

Taking into account the stages of the disassembly or maintenance

|

Editors- admin_andrei - 901 words.

View count: 4757